It is shown that the perpendicular distance between the involutes for all gears with the same module always corresponds to the perpendicular distance between two adjacent flanks. The basic relationship between a gear and a rack (“tool profile”) is shown in the figure below. For this purpose, for example, gear shaping can be used, which will be described in more detail in the next section. However, this process cannot be used to produce internal gears.

The cutting performance of gear hobbing is very high, so that especially very thick gears can be produced in a relatively short time. Figure: Standard reference profile for a hob cutter The actual tool profile is created from the so-called standard reference profile after consideration of the root fillet and the clearance c. The center line of the profile corresponds to the pitch line.

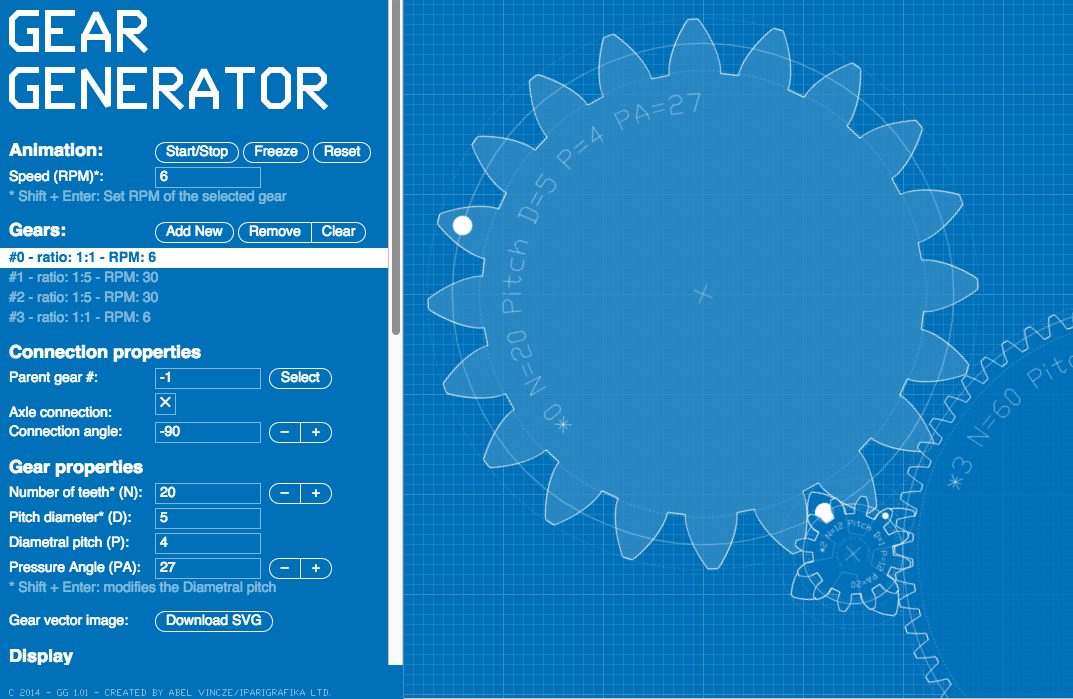

The tool flanks are inclined against the vertical by the standard pressure angle α 0. The geometry of the rack-shaped tool profile depends on the desired flank profile of the gear tooth. Animation: Gear cutting with a hob (hobbing) When manufacturing a gear with 18 teeth, the rotational speed of the hob must therefore be 18 times higher than the speed of the gear.

The number of teeth on the gear reflects the ratio of the rotational speeds. The rotational speed between gear and hob must therefore be matched to each other so that the teeth can form correctly. Gear and hob form a kind of “ worm gear” in their motion sequence. In this respect, the pitch of the cutters corresponds exactly to the tooth pitch of the gear. During one rotation of the hob, the gear moves forward by one tooth. The cutting edges of a hob are straight-flanked and wrap spirally around the milling tool (similar to the thread of a screw). The cross-sectional profile of a hob is equal to that of a rack! Figure: Gear cutting with a hob (hobbing)Īs the gear rotates, the teeth of the hob, which also rotate, continue to mill inwards into the gear over time until the final depth is reached. Involute gears are often manufactured by hobbing.

0 kommentar(er)

0 kommentar(er)